In this walkthrough, you will learn how to generate a bulk pick for production orders. Bulk picks are used when you want to pick enough items to fulfill more than one production order.

Bulk picking can be used when one item is needed for different production orders. Instead of picking the item separately for each production order, bulk picking calculates the following:

Quantity of the items that are required for all of the selected production orders

Bin(s) from which the items should be picked

When creating the bulk pick, you have the option of breaking the bulk item before moving it, or of moving the full quantity without breaking it.

Function Background

Function Background

When a location is set up that does NOT require non-directed consumption picks, then bulk picks can be used to pick the ingredients for multiple production orders. Using the Inventory Movement window, the bulk pick will calculate the total amount of ingredients that are required for the selected production orders. Once the inventory movement is registered, the items are moved to the bin that has been defined for the To-Production Bin Code for the location.

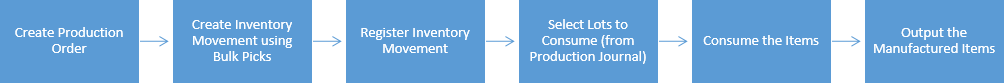

When using bulk picks with a production order, the process is as follows:

Note: In order to follow this process, the Require Non-directed Consumption Pick check box cannot be selected for the location.

About This Walkthrough

About This Walkthrough

This walkthrough provides an overview on how to do the following:

Story

Story

The JF company manufactures and sells YOGIES chocolates from its SEATTLE location. The W100420 ORGANIC MINI PRETZEL and the W100120 FAT FREE MINI PRETZEL share a couple of the same ingredients: R100840 YEAST and R100750 STANDARD ROCK SURFACE SALT.

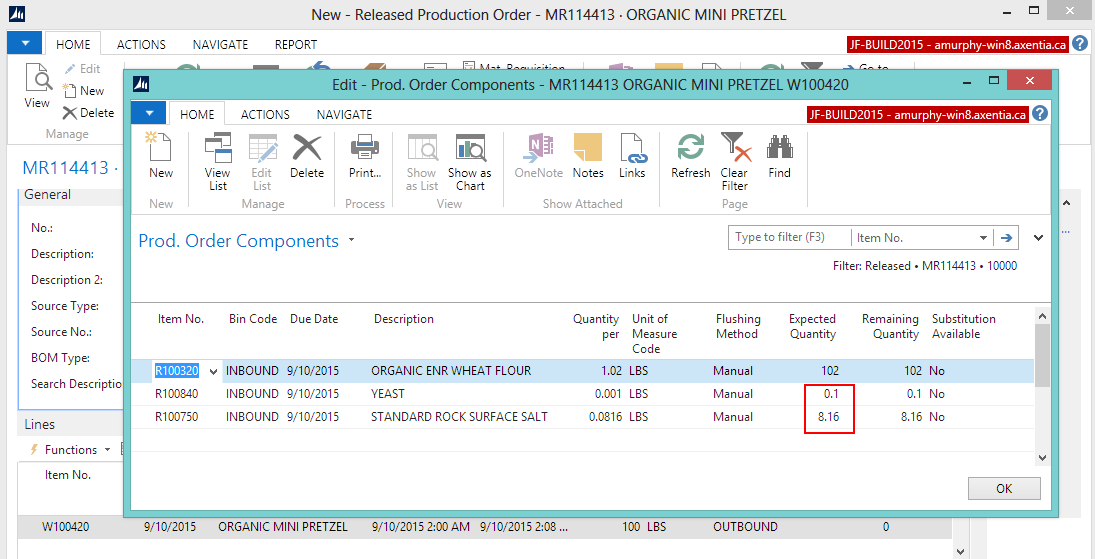

A released production order was created for 100 pounds of the ORGANIC MINI PRETZEL item. When you look at the production order components, you can see that 102 pounds of FLOUR, 0.1 pounds of YEAST, and 8.16 pounds of SALT are required.

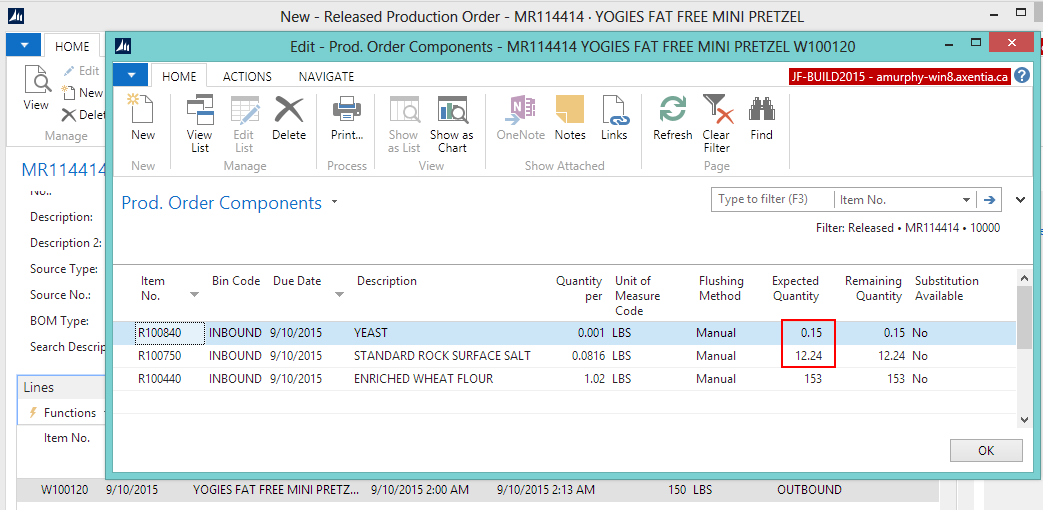

A released production order was also created for 150 pounds of the YOGIES FAT FREE MINI PRETZEL item. When you look at the production order components, you can see that 153 pounds of WHEAT FLOUR, 0.15 pounds of YEAST, and 12.24 pounds of SALT are required.

Both productions orders require R100840 YEAST and R100750 SALT, which ends up being a total of 0.25 pounds of YEAST, and 20.4 pounds of SALT.

Instead of moving each item individually to the INBOUND bin, the Inventory Movement window is used to create a bulk pick, which will pick enough YEAST and SALT to fulfill both of the production orders.

Since SALT is purchased in bags but consumed in pounds, a bag will need to be "broken" in order to consume the quantity required for the production order. When creating the bulk picks, two scenarios are possible:

- Break the bulk item, and then move the item.

- Move the full break bulk item.

Once the bulk pick is created and the movement is registered, the items are moved to the INBOUND bin, which is the To-Production Bin Code for the SEATTLE location.

Prerequisites

Prerequisites

Production orders are defined

-

Sufficient inventory exists in the bins at the selected location. If there is not enough inventory to fulfill the production orders, then only the available inventory will be listed for the bulk pick. For example, if the production orders called for 660kgs of flour, but only 500kgs were in inventory, then the bulk pick will only show 500kgs.

-

The To-Production bin of the location does not already have enough inventory to fulfill the production orders. If enough inventory already exists in the To-Production bin, then the item will not be added to the bulk pick.

-

Allow Breakbulk is selected for the location. If Allow Breakbulk isn't selected, then any items that are not in consumable units will not be added to the bulk pick.

Creating a Bulk Pick-Breaking the Bulk Item

Creating a Bulk Pick-Breaking the Bulk ItemThe following procedure explains how to create a bulk pick for production orders due on a certain day. The bulk pick will be "break" any items that aren't in consumable units, and then move the required quantity to the INBOUND bin.

In the Search box, enter inventory move, and select Inventory Movements. The Inventory Movements window opens.

Click New.

Tab off of the field to automatically populate the No. field.

-

Select SEATTLE for the Location Code field.

-

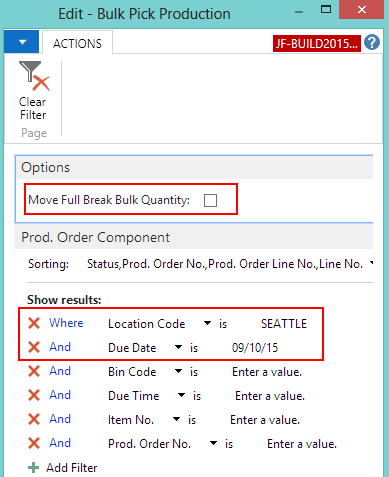

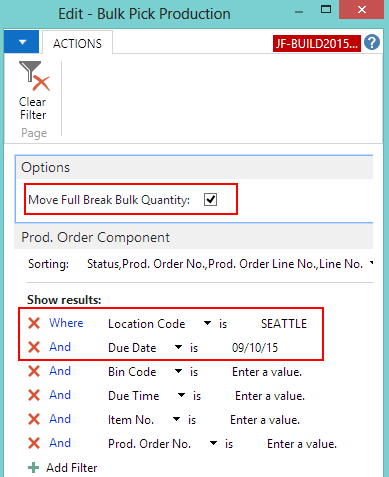

On the Home tab, in the Process group, choose Bulk Pick Production. The Bulk Pick Production report opens.

-

On the Options tab, clear the Move Full Break Bulk Quantity check box. This means that an item will be broken into units required for the pick, and only the required amount will be moved to the INBOUND bin.

-

For the first filter line, select Location Code is SEATTLE.

-

For the second filter line, select Due Date is 09/10/15. This narrows down the picks to production orders that are due on September 10, 2015.

-

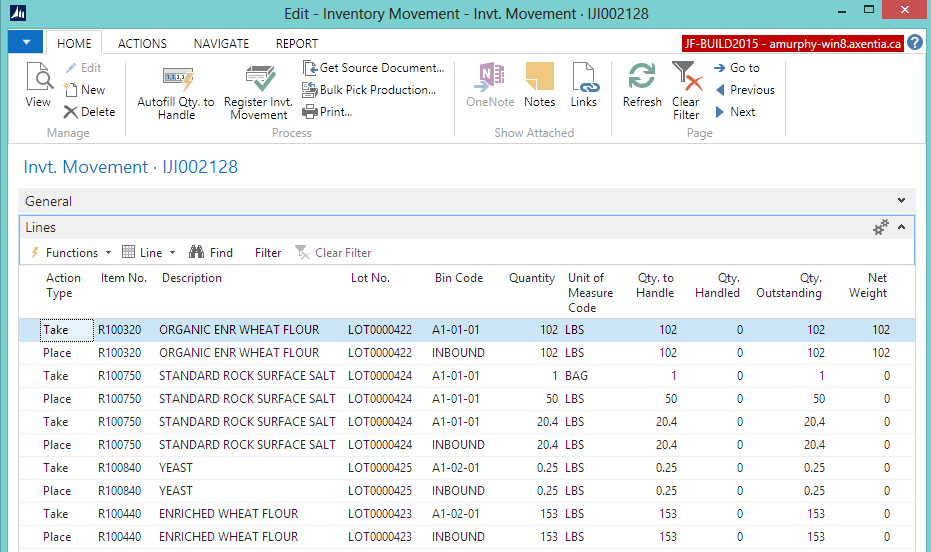

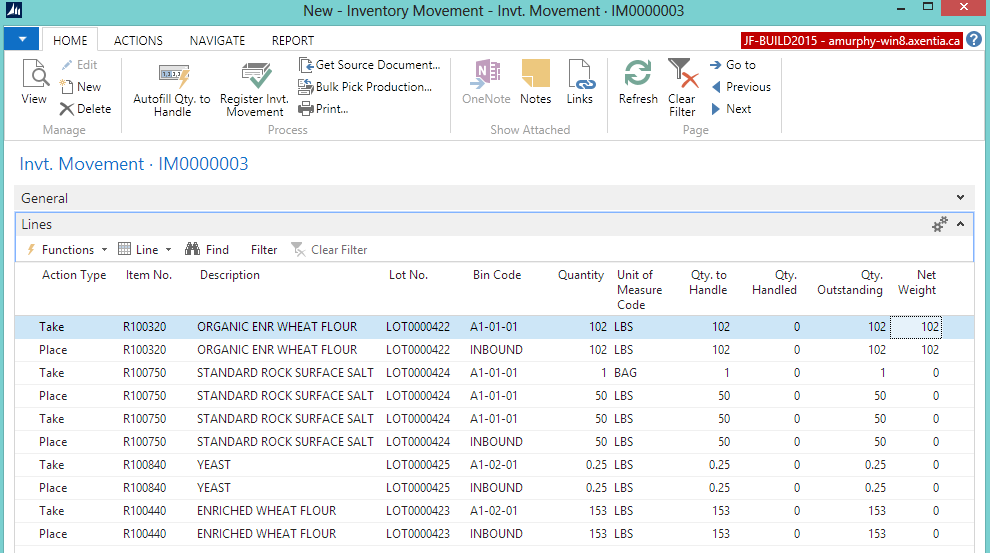

Click OK. The lines show the quantities that need to be taken and placed for all of the production orders that are due on September 10, 2015 at the SEATTLE location.

You can see that the items for the MR114413 and MR114414 released production orders are listed.

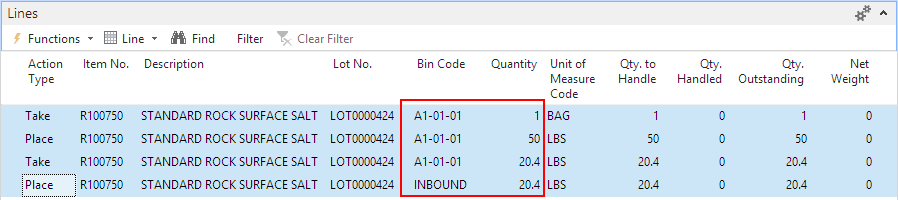

Production order MR114413 required 8.16 pounds of SALT and MR114414 required 12.24 pounds of salt, so 20.4 pounds of salt needed to be moved to the INBOUND bin.

Since SALT was purchased in bags, and is consumed in pounds, a bag needed to be "broken" in order to take the required pounds. A bag weighs 50 pounds. When creating the bulk pick, the Move Full Break Bulk Quantity check box was not checked. As a result, 1 bag was taken from the A1-01-01 bin and 50 pounds were placed back into the A1-01-01 bin. Then the required 20.4 pounds were taken from the A1-01-01 bin and placed into the INBOUND bin.

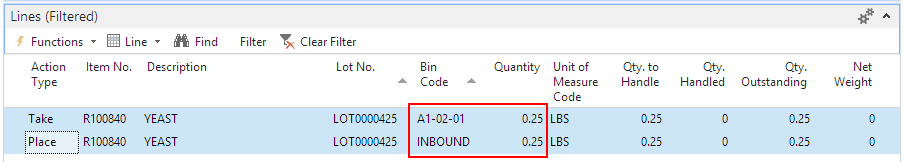

Since both production orders required YEAST, a total of 0.25 pounds of yeast were moved to the INBOUND bin. Production order MR114413 required 0.1 pounds of salt and MR114414 required 0.15 pounds of salt.

On the Home tab, in the Process group, choose Register Invt. Movement.

-

Click Yes to register the inventory movement. The items are moved to the INBOUND bin.

Creating a Bulk Pick-Moving the Full Quantity

Creating a Bulk Pick-Moving the Full Quantity

The following procedure explains how to create a bulk pick for production orders due on a certain day. The bulk pick will "break" an item into consumable units, and then will move the full quantity to the INBOUND bin.

In the Search box, enter inventory move, and select Inventory Movements. The Inventory Movements window opens.

Click New.

Tab off of the field to automatically populate the No. field.

-

Select SEATTLE for the Location Code field.

-

On the Home tab, in the Process group, choose Bulk Pick Production. The Bulk Pick Production report opens.

-

On the Options tab, select the Move Full Break Bulk Quantity check box. This means that a full unit of the item will be moved to the INBOUND bin, and then it will be broken in to units that can be used for the production order.

-

For the first filter line, select Location Code is SEATTLE.

-

For the second filter line, select Due Date is 09/10/15. This narrows down the picks to production orders that are due on September 10, 2015.

-

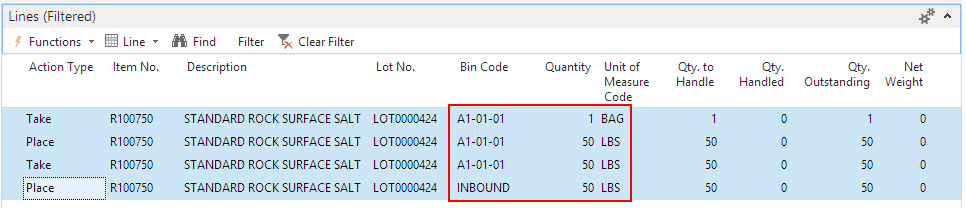

Click OK. The lines show the quantities that need to be taken and placed for all of the production orders that are due on September 10, 2015 at the SEATTLE location.

You can see that the items for the MR114413 and MR114414 released production orders are listed.

Since both production orders required SALT, a total of 20.4 pounds of salt is needed to fulfill both orders.

Since SALT was purchased in bags, and is consumed in pounds, a bag needs to be "broken" in order to take the required pounds. A bag weighs 50 pounds. When creating the bulk pick, the Move Full Break Bulk Quantity check box was checked. As a result, the bag was converted to pounds. Then ALL 50 pounds were taken from the A1-01-01 bin and placed into the INBOUND bin.

Since both production orders required YEAST, a total of 0.25 pounds of yeast were moved to the INBOUND bin.

On the Home tab, in the Process group, choose Register Invt. Movement.

-

Click Yes to register the inventory movement. The items are moved to the INBOUND bin.

See Also

Warehouse WalkthroughsAbout Bulk Picks