In this walkthrough, you will learn how to process a purchase order for variable weight items in the Lot Everywhere scenario.

When using the Lot Everywhere scenario, the total weight of all of the cases for a specific lot is recorded for all INBOUND, MOVE and OUTBOUND transactions.

Function Background

Function Background

Variable weight is part of inventory management, and is used for items that are purchased, manufactured and sold in discreet units (for example, CASE or BOX) but where each unit has a variable weight and is therefore priced by weight.

When using the Lot Everywhere scenario for variable weight, it means that a total weight is assigned to the entire lot rather than individual cases.

For INBOUND, MOVE and OUTBOUND transactions, the weight of the entire lot is posted. The Item Ledger entries, and Warehouse entries record a transaction for each lot number.

The item tracking code, which is assigned to an item, is how JustFoodERP determines how variable weights are handled.

About This Walkthrough

About This Walkthrough

This walkthrough provides an overview on how to do the following:

- Creating a variable weight item

- Create an item tracking code

- Create an item

- Creating a variable weight production order

- Registering a variable weight warehouse pick

- Consuming the raw materials and outputting the finished good

Story

Story

The JF Company purchases and receives bulk meat items, and then manufactures cases of sausage. The cases of sausage are sold by weight.

The SEATTLE location has been set up as a warehouse that uses non-directed picks and put-aways. At the Seattle location, cases of Italian sausage (VW-LOTE-FG-ITAL_SAUS) are going to be manufactured using purchased bulk ground beef (VW-LOTE-BEEF_GROUND) and bulk ground pork (VW-LOTE-PORK_GROUND). The bulk ground beef and bulk ground pork are both variable weight items and have associated weights.

Each case of the Italian sausage (VW-LOTE-FG-ITAL_SAUS) is expected to weigh 25 pounds. When 2 cases of Italian sausages are manufactured, the actual total weight of the cases ends up being 49.6 pounds.

Prerequisites

Prerequisites

-

Number series was defined for purchase orders

-

Lot number series was defined on the No. Series window

-

Units of measure were defined on the Units of Measure window

-

Item category was defined on the Item Categories window

-

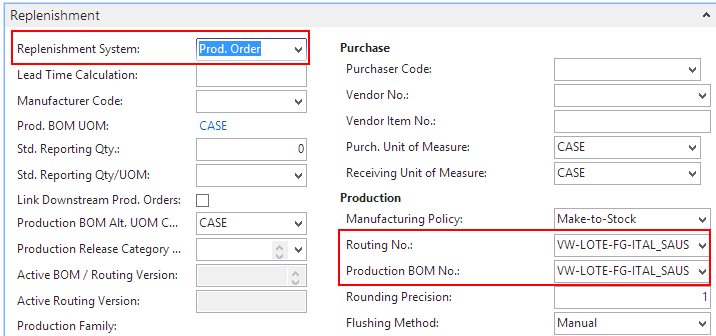

Routing number and production BOM number were created, which are used for the new variable weight item.

-

Warehouse location was set up for non-directed picks and put-aways

-

Employee performing the steps was set up as a warehouse employee for the SEATTLE location

Creating a Variable Weight Item

Creating a Variable Weight Item

The following procedures explain what needs to be done in order to create a variable weight item for the Lot Everywhere scenario:

To Create an Item Tracking Code

To Create an Item Tracking Code

-

In the Search box, enter item tracking, and choose Item Tracking Codes. The Item Tracking Codes window opens.

-

Click New. The Item Tracking Code Card window opens.

-

Enter VW-S2-LOTE in the Code field.

-

Enter Variable Weight Scenario 2 Lot Everywhere in the Description field.

-

On the Serial No. FastTab, make sure all of the check boxes are cleared.

-

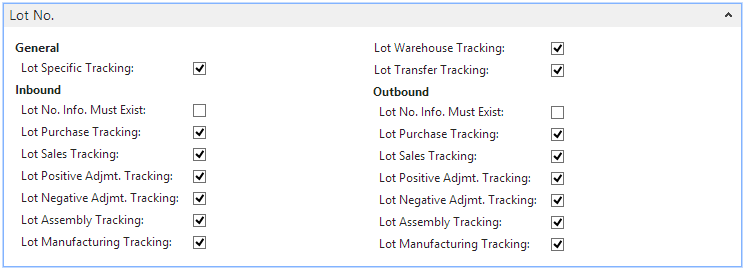

On the Lot No. FastTab, select all of the check boxes except for Lot No. Info Must Exist under Inbound and Outbound.

-

On the Misc. FastTab, select the Variable Weight Tracking check box.

-

Click OK.

To Create a Variable Weight Item

To Create a Variable Weight Item

A variable weight item needs to be created for the manufactured Italian sausage (VW-LOTE-FG-ITAL_SAUS). The manufactured sausage is expected to weigh 25 pounds per case

-

In the Search box, enter items, and choose Items.

-

Click New.

-

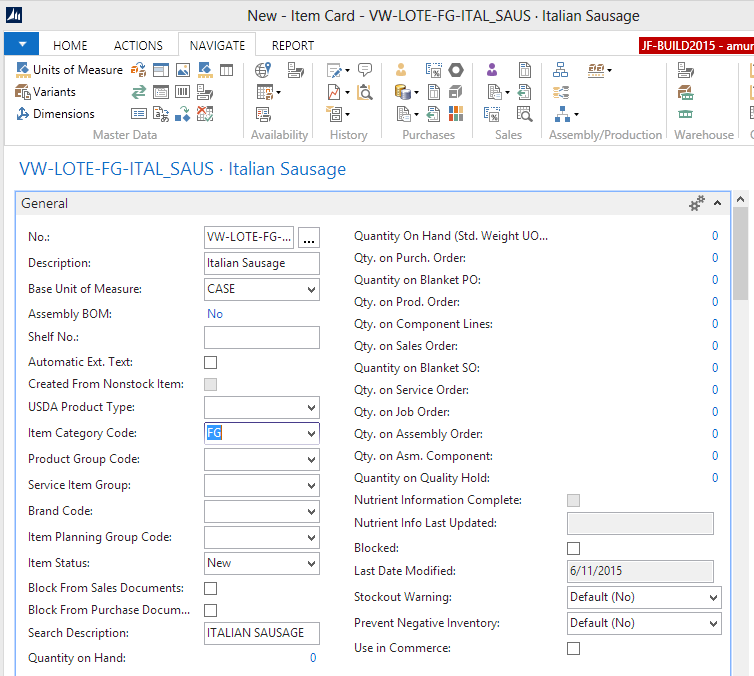

Enter VW-LOTE-FG-ITAL_SAUS in the No. field.

-

Enter Italian Sausage in the Description field.

-

Create the item's units of measure.

-

On the Navigate tab, in the Master Data group, choose Units of Measure. The Item Units of Measure window opens.

-

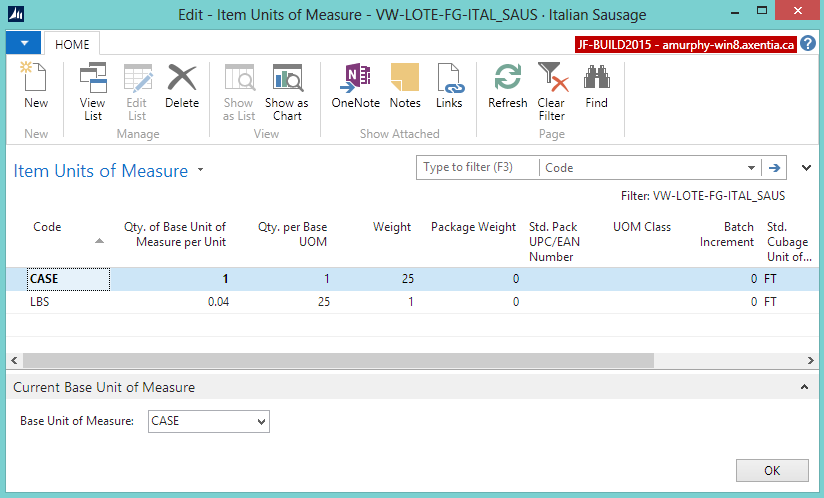

Add the following records:

Code Qt. per Base UOM Weight CASE 1 25 LBS 25 1 -

Select CASE in the Base Unit of Measure field.

-

Click OK.

The Base Unit of Measure field is populated with CASE on the General FastTab.

-

Select FG for the Item Category Code field.

-

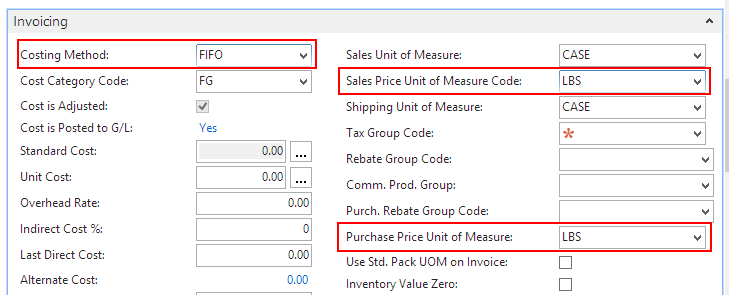

Enter information on the Invoicing FastTab.

-

Select FIFO in the Costing Method field.

-

Select the LBS in the Sales Price Unit of Measure Code field.

-

Select the LBS in the Purchase Price Unit of Measure field.

-

Enter information on the Replenishment FastTab.

-

Enter information on the Item Tracking FastTab.

-

Select VW-S2-LOTE in the Item Tracking Code field.

-

Select LOT in the Lot Nos. field.

-

Enter 6M in the Expiration Calculation field.

-

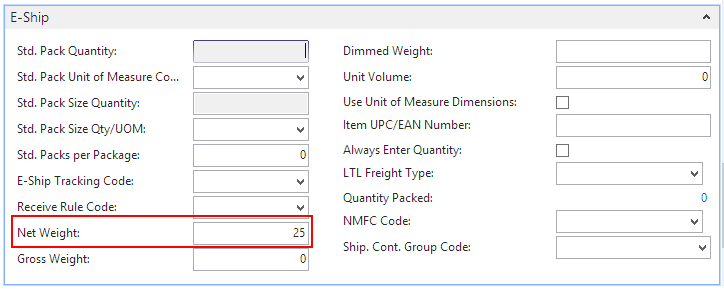

On the Actions tab, in the Functions group, choose Weight>Calculate Net Weight.

The Net Weight field is populated on the E-Ship FastTab. The net weight is calculated based on the defined units of measure. The net weight flows to document lines (sales, picks, warehouse entries).

-

Click OK. The Item Card window is closed.

Creating a Variable Weight Production Order

Creating a Variable Weight Production Order

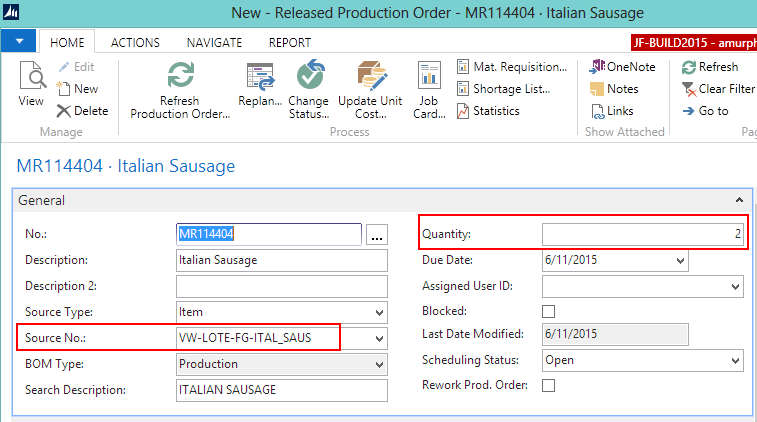

In the Search box, enter released, and select Released Prod. Orders.

Click New. The Released Production Order window opens.

-

Tab off of the No. field.

-

In the Source No. field, select VW-LOTE-FG-ITAL_SAUS.

-

Enter 2 in the Quantity field.

-

On the Posting FastTab, select SEATTLE in the Location Code field, and tab off of the field.

-

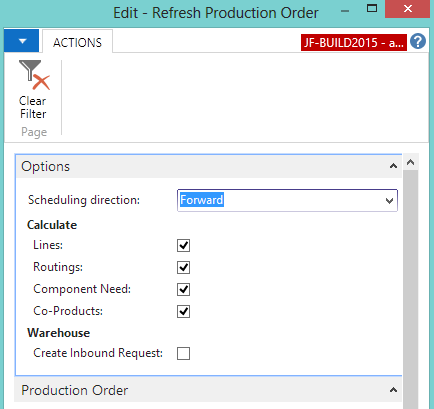

On the Home tab, in the Process group, choose Refresh Production Order. The Refresh Production Order window opens.

-

Select Forward in the Scheduling direction field.

-

Select all of the Calculate check boxes.

-

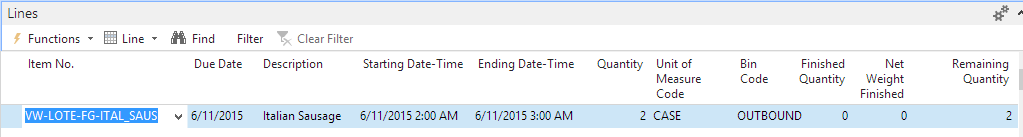

Click OK. The Lines FastTab is populated.

At this point, the Net Weight Finished field is not populated.

Registering a Warehouse Pick

Registering a Warehouse Pick

The warehouse pick determines from where to pick the items. Since the ground beef and ground pork are variable weight items, the total weight of the cases needs to be entered.

Prerequisites

In the Search box, enter released, and select Released Prod. Orders.

Select the released production order that was created for the variable weight item. In this case, MR114404.

-

On the Actions tab, in the Warehouse group, choose Create Whse. Pick. The Whse. Source-Create Document window opens.

-

Click OK.

-

Click OK at the message that a Pick Activity was created.

-

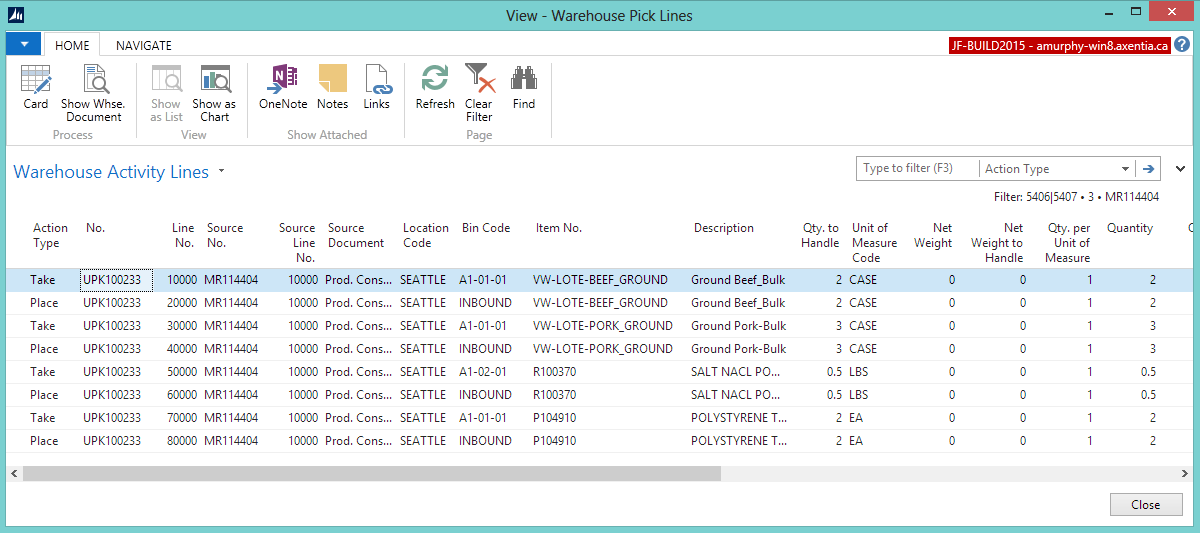

On the Navigate tab, choose Put-away/Pick Lines/Movement Lines. The Warehouse Pick Lines window opens.

The lines show where you're taking items from, and where you're placing them. At this point, the Weight fields do not have a value for the variable weight items (VW-LOTE-BEEF_GROUND and VW-LOTE-PORK-GROUND).

-

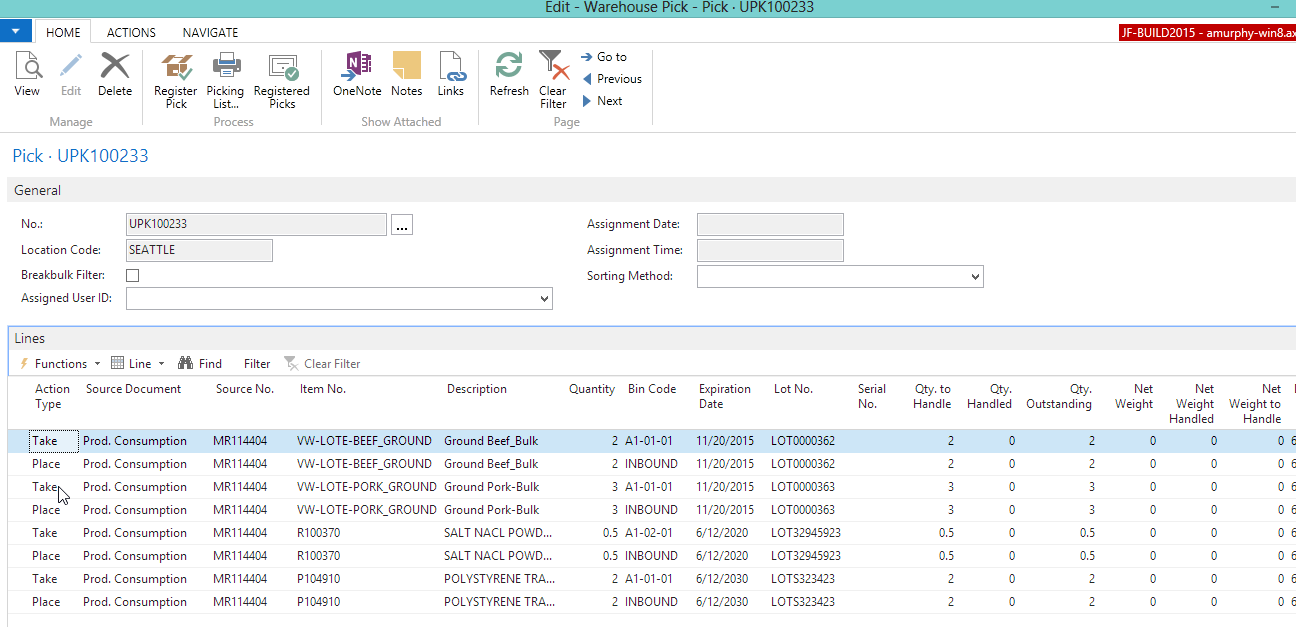

On the Home tab, in the Process group, choose Card. The Warehouse Pick window opens. The items that are required to make the finished good are listed with their lot numbers.

The Net Weight fields are not populated.

-

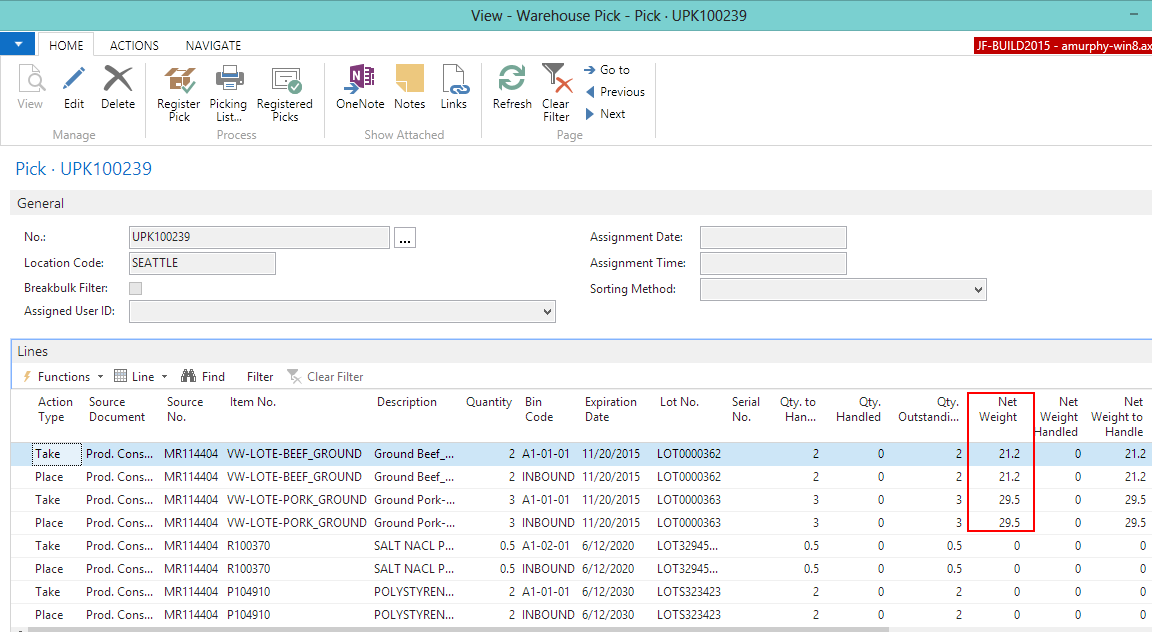

For the Take line of the VW-LOTE-BEEF_GROUND item, enter 21.2 in the Net Weight field. This is the total weight of the 2 cases.

-

For the Take line of the VW-LOTE-PORK-GROUND item, enter 29.5 in the Net Weight field. This is the total weight of the 3 cases.

-

On the Home tab, in the Process group, choose Register Pick. The Warehouse Pick window closes. The quantity of items needed for the BOM are moved to the bin defined in the Inbound BOM Bin Code field on the location card.

Consuming the Raw Materials and Outputting the Finished Good

Consuming the Raw Materials and Outputting the Finished Good

The raw materials have been moved to the INBOUND bin used for consumption. The 2 cases of Italian sausage can be outputted, and the total weight of the cases will be recorded.

Prerequisites

Open the released production order if it is not already open.

-

On the Lines FastTab, select the line for the VW-LOTE-FG-ITAL_SAUS item.

-

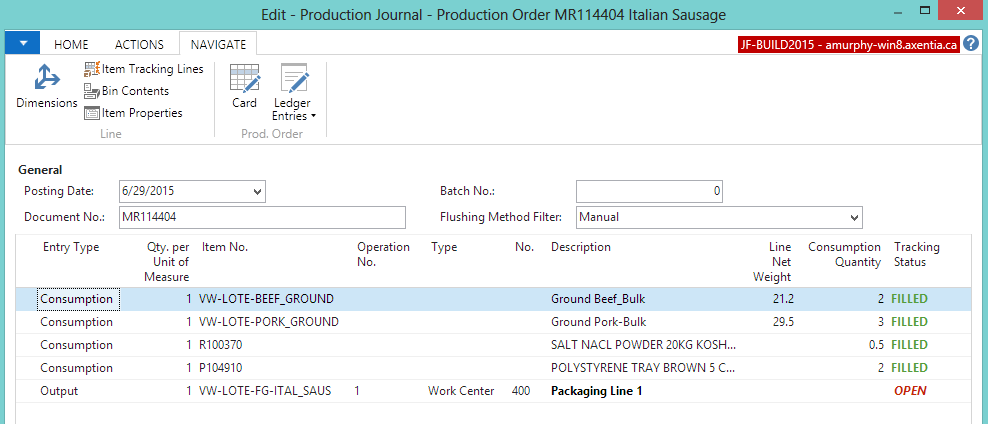

Choose Line>Production Journal. The Production Journal window opens.

If you look at the Item Tracking Lines for the VW-LOTE-BEEF-GROUND item, you can see the details of the picked item including the net weight.

-

Enter the tracking information for the sausage line.

Select the VW-LOTE-FG-ITAL_SAUS line.

-

Enter 2 in the Output Quantity field.

-

On the Navigate tab, choose Item Tracking Lines. The item Tracking Line window opens.

-

On the Actions tab, choose Assign Lot No.

-

Enter 2 in the Quantity (Base) field.

-

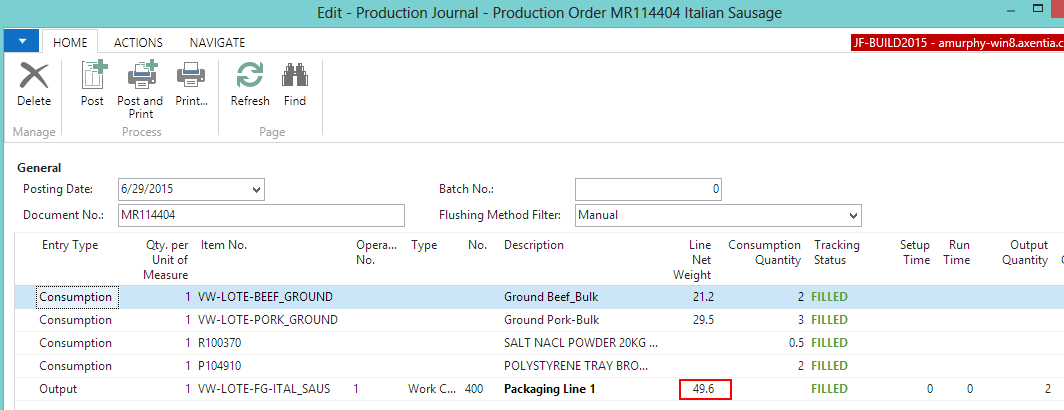

Enter 49.6 in the Net Weight field. The net weight of the VW-LOTE-FG-ITAL_SAUS item is expected to be around 25 pounds. The combined weight of two of the manufactured cases ended up being 49.6 pounds.

Click OK. The Line Net Weight field is populated with 49.6.

-

On the Home tab, in Process group, choose Post.

-

Click Yes at the question asking if you want to post the journal lines.

-

Return to the Released Production Order window.

-

Change the status of the production order.

On the Home tab, in the Process group, choose Change Status.

-

Select Finished.

-

Click Yes.

-

Click OK. The Released Production Order window is closed.

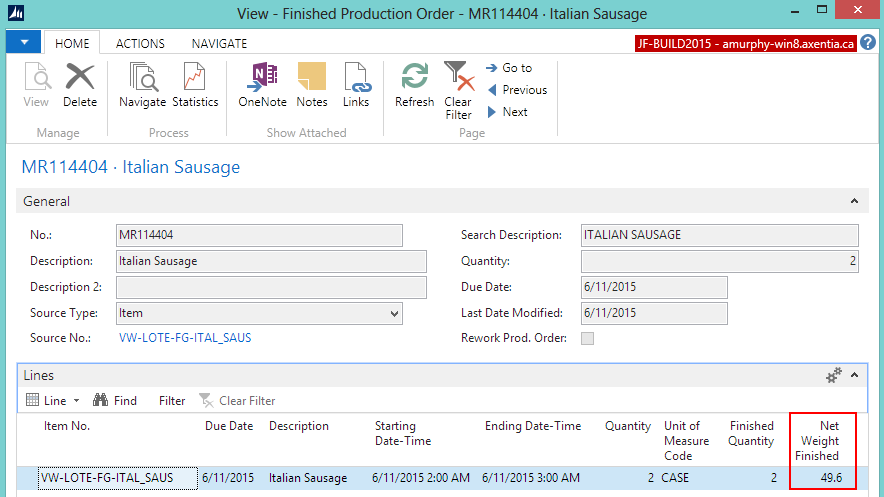

On the Finished Production Order window, the Net Weight Finished field shows the total weight of the finished item.

On the Item Ledger Entries window, the Net Weight field shows the total weight of the VW-LOTE-FG-ITAL_SAUS item that was manufactured.

On the Warehouse Entries, the Net Weight field shows the total weight of the VW-LOTE-FG-ITAL_SAUS item that was manufactured.

Video

Video

See Also

© 2015 Microsoft and IndustryBuilt Software. All rights reserved.

JustFoodERP 2015 Feature Pack 1 (8.00.01.00) | July 2015