In this walkthrough, you will learn what needs to be set up in order to have an item's lot property inherit a value from the results of a quality audit.

The walkthrough uses a Receiving quality audit, but the same concept applies to any type of quality audit for a lot-tracked item.

Function Background

Function Background

With quality audits, you first need to set up the quality measures and quality procedures.

Quality measures are individual checks that need to be completed in a quality audit. Quality measure codes are assigned to quality procedures. The same quality measure code can be assigned to multiple quality procedures. Property codes can be assigned to a quality measure code.

A quality procedure is a grouping of quality measure codes. The quality procedure can then be set up so that when an event occurs, a unique quality audit is generated based on that quality procedure. The same quality procedure can be associated with different events but a unique quality audit will always generated when the event occurs.

A quality audit, that contains quality measure codes with a property code, will push the results of the quality measure to the item's lot property.

About This Walkthrough

About This Walkthrough

This walkthrough provides an overview on how to do the following:

- Set Up a Quality Procedure with a Property Code

- Create the property

- Create a quality measure code

- Create a quality procedure

- Assign the quality procedure to an item

- Generate the Receiving quality audit

- Generate a Receiving quality audit

- View the Receiving quality audit

- Perform the Receiving quality audit

- Perform a passed Receiving quality audit

- View the item's lot property

Story

Story

The JF company has ordered 45 kilograms of whole cranberries. When the cranberries are received, they need to be visually inspected in order to determine the grade of the product. Since the grade not only applies to the quality audit, but also to the item's lot, the JF company wants the result of the quality audit grading to be copied over to the item's lot property.

Prerequisites

Prerequisites

-

GRADE property group code is defined on the Property Groups window.

-

Number series is defined for the Quality Procedure Setup Nos. field on the Quality Setup window.

-

Number series is defined for the Quality Audit Nos. field on the Quality Setup window

Setting Up a Quality Procedure with a Property Code

Setting Up a Quality Procedure with a Property CodeThe following procedures explain how to set up a quality procedure, which will generate a quality audit that, when completed, will push the results to an item's lot property.

- Create the property

- Create a quality measure codes

- Create a quality procedure

- Assign the quality procedure to an item

To Create the Property

To Create the Property

In this walkthrough, the GRADE property will apply to the whole cranberries item's lot, which allows users to see the grade of a particular lot of cranberries.

In the Search box, enter properties, and select Properties.

Click New.

Add the following record:

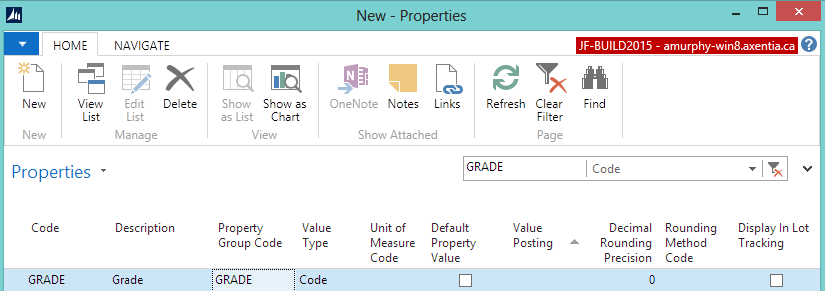

Code Description Property Group Code Value Type GRADE Grade GRADE Code On the Navigate tab, choose Code Values. The Code Property Values window opens.

Note: Code property values are not required in order for an item to inherit the property from a quality audit.

-

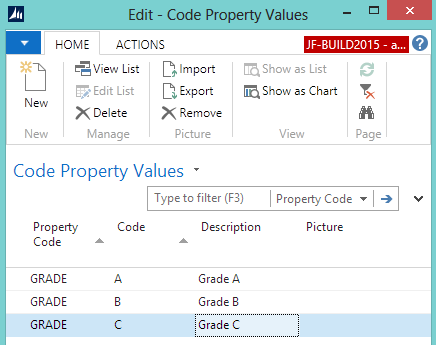

Add the following records:

Property Code Code Description GRADE A Grade A GRADE B Grade B GRADE C Grade C -

Click OK to close the Code Property Values window.

-

Click OK to close Properties window.

To Create Quality Measure Codes

To Create Quality Measure Codes

The quality measure codes represent the different ways of recording the quality of an item. Quality measure codes need to be created for each of the conditions that need to be checked before releasing the item into inventory.

For the JF company, that means that a quality measure code needs to be created for the following:

- Visual Check

In the Search box, enter quality measure, and select Quality Measure Codes.

Click New.

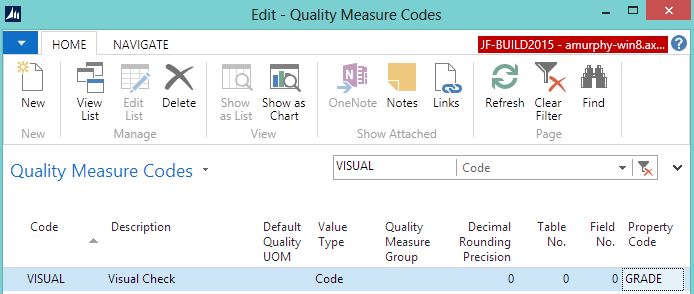

Add the following records:

Code Description Value Type Property Code VISUAL Visual Check Code GRADE On the Navigate tab, choose Quality Measure Code Values. The Quality Measure Code Values window opens.

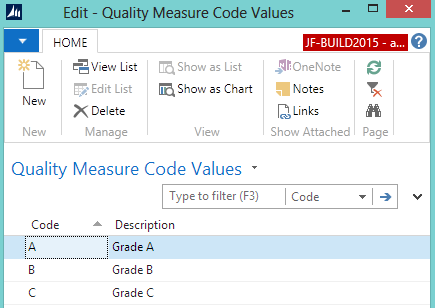

Add the following records:

Note: Code property values and quality measure codes are not required in order for an item to inherit the property from a quality audit. But if you do use code property values and quality measure codes, it is recommended that you keep the code values the same in order to keep the data consistent.

Code Description A Grade A B Grade B C Grade C -

Click OK to close the Quality Measure Code Values window.

-

Click OK to close the Quality Measure Codes window.

To Create a Quality Procedure

To Create a Quality Procedure

A quality procedure groups quality measure codes, and allows you to record the desired test results. The quality procedure can then be assigned to an item. When a warehouse receipt is generated, the quality procedure is used to create a quality audit related to the item on the warehouse receipt.

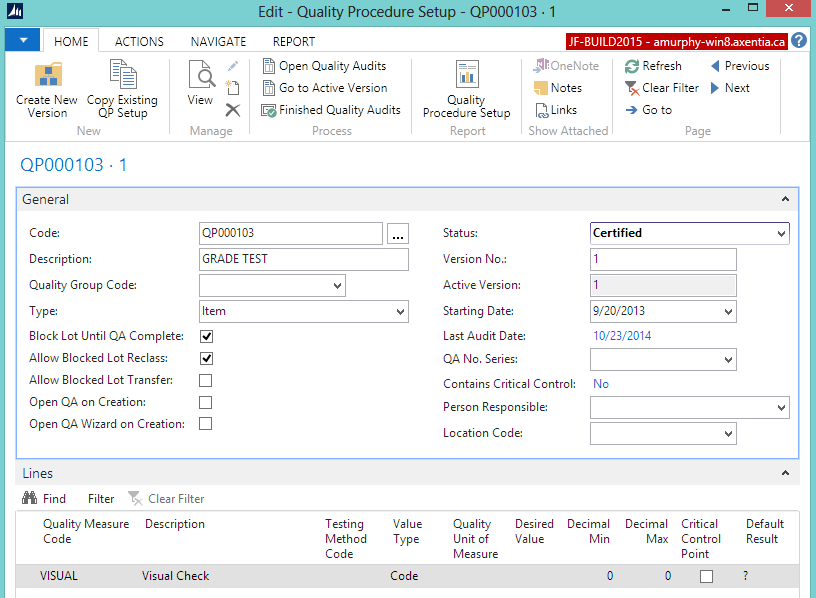

For the JF company, a GRADE TEST quality procedure is being created.

In the Search box, enter quality procedures, and select Quality Procedures.

Click New. The Quality Procedure Setup window opens.

Enter information on the General FastTab.

Field Description Code

Tab off the field to have the system assign a code. (For a system-assigned code, a number series must be defined for the Quality Procedure Setup Nos. field on the Quality Setup window.)

Description

Enter GRADE TEST.

Type

Select Item.

Block Lot Until QA Complete

Select the check box. This prevents transactions from occurring with this itemís lot until the quality audit is completed and passed.

Allow Blocked Lot Reclass Select the check box. This allows blocked lots to be moved within a location. Add the following records to the Lines FastTab.

Quality Measure Code VISUAL

On the General FastTab, change the Status field to Certified.

Click OK.

To Assign the Quality Procedure to an Item

To Assign the Quality Procedure to an Item

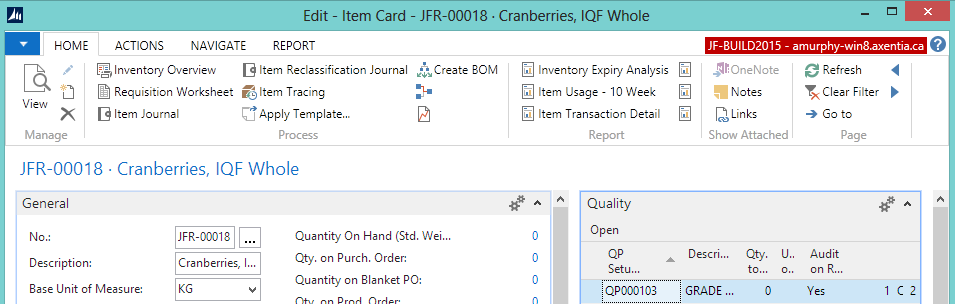

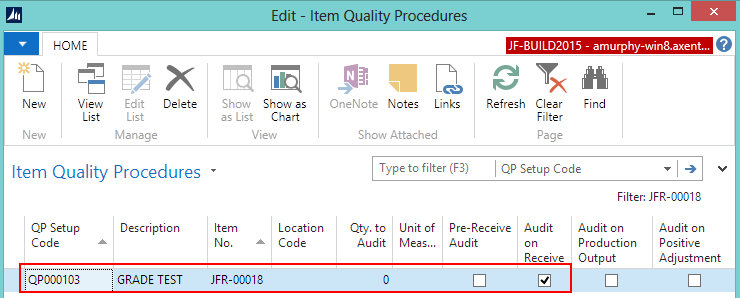

The GRADE TEST quality procedure needs to be assigned to the whole cranberries item (JFR-00018). When the item is received, the Receiving quality audit will be automatically created.

In the Search box, enter items, and select Items.

Open the item card for JFR-00018.

Ensure that the Quality FactBox is displayed.

Click Open in the Quality FactBox. The Item Quality Procedures window opens.

Add a line for the GRADE TEST quality procedure:

- QP Setup Code: QP000103

- Audit on Receive: Select the check box.

Click OK. The GRADE TEST quality procedure is added to the Quality FactBox on the Item card.

Generating a Receiving

Quality Audit

Generating a Receiving

Quality Audit

This section contains the following procedures:

Prerequisites

Setup procedures were completed.

A warehouse receipt was created for the whole cranberry (JFR-00018) item.

The location associated with the purchase order is set up for warehouse receiving since this walkthrough is using warehouse receipts. In this case, the location is MAIN.

The person performing these steps is a warehouse employee. You need to be a warehouse employee in order to access the warehouse receipt.

To Generate a Receiving Quality Audit

To Generate a Receiving Quality Audit

In the Search box, enter warehouse receipts, and select Warehouse Receipts (/Departments/Warehouse/Planning & Execution).

Open the warehouse receipt that was created for the whole cranberry (JFR-00018) item.

Enter a value in the Qty. to Receive field.

-

Assign a lot number to the item. In this case, LOT0000296.

On the Home tab, in the Process group, click Post Receipt.

Click Yes at the question asking if you want to post the receipt.

-

Click OK at the message that a quality audit was created.

-

Click OK at the message that the source documents were posted. The Posted Whse. Receipt window opens.

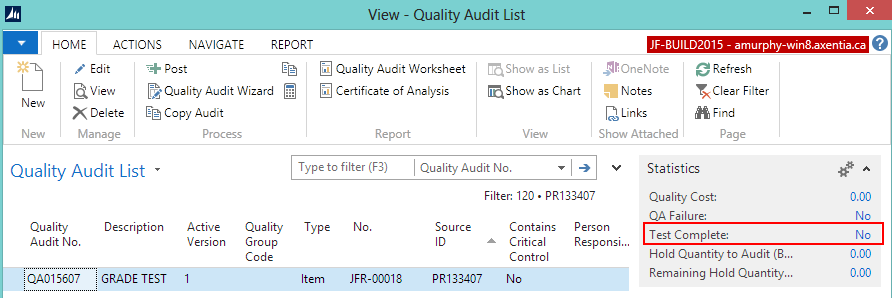

To View the Receiving Quality Audit

To View the Receiving Quality Audit

In the Search box, enter purchase orders, and select Purchase Orders.

Open the purchase order associated with the quality audit. In this case, PO0026371.

On the Navigate tab, in the Documents group, choose Receipts. The Posted Purchase Receipts window opens.

-

On the Navigate tab, in the Receipt group, choose Quality Audits. The Quality Audit List window opens.

The quality audit, which was generated when the warehouse receipt was posted, is listed.

The Test Complete field in the Statistics FactBox shows that the quality audit has not been completed.

Performing the Receiving Quality Audit

Performing the Receiving Quality Audit

Using a defined set of standards, the warehouse employee checks the received cranberries to determine what grade to assign them. The resulting grade is then inherited by the item's lot property.

This section contains the following procedures:

To Perform a Receiving Quality Audit

To Perform a Receiving Quality Audit

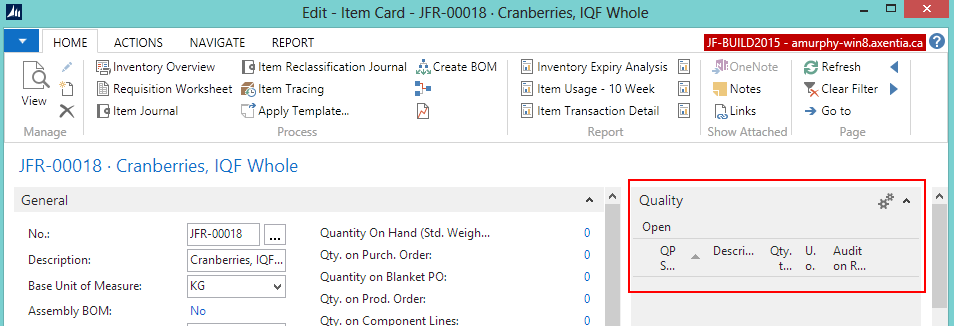

In the Search box, enter items, and select Items.

Open the item card for the for the whole cranberry (JFR-00018) item.

On the Navigate tab, in the Quality group, click Quality Audits. The Quality Audit List window opens.

Select the QA015607 quality audit.

-

On the Home tab, in the Process group, choose Quality Audit Wizard. The Quality Audit wizard opens.

-

Click Next.

-

Enter the results of the visual check.

In the Result Value field, select B. This result will be copied over to the item's lot property.

-

In the Result field, select Pass. The Test Complete check box is automatically selected.

-

Click Next.

-

Finish the audit.

Select the Post audit on Finish check box.

Select the Close wizard on Finish check box.

Click Finish.

The quality audit is posted.

To View the Item's Lot Property

To View the Item's Lot Property

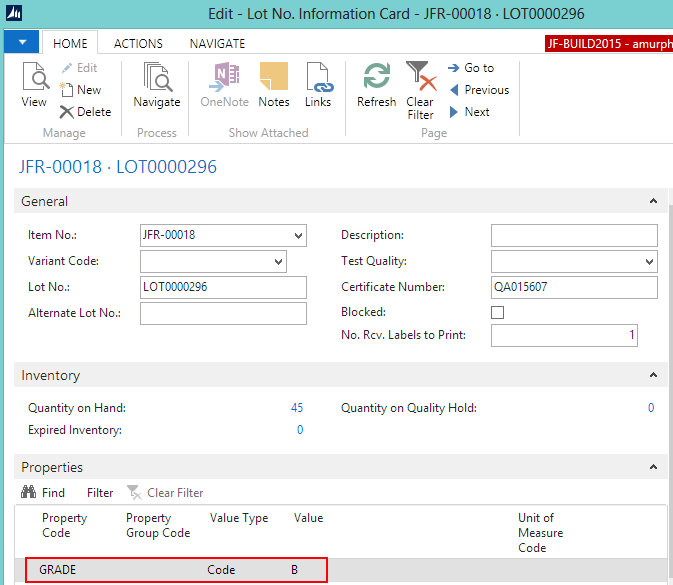

Because a property code was associated with the VISUAL quality measure code, when a quality audit with that quality measure code is completed, the item's lot property is updated with test result.

In the Search box, enter items, and select Items.

Open the item card for the for the whole cranberry (JFR-00018) item.

On the Navigate tab, in the Availability group, choose Entries>Ledger Entries. The Item Ledger Entries window opens.

-

Select the LOT0000296 line, which is the lot that was received and graded.

-

On the Navigate tab, in the Entry group, choose Lot No. Information. The Lot No. Information Card window opens.

On the Properties FastTab, you can see that lot LOT0000296 has a GRADE property value of B. That value was inherited from the results of the QA015607 quality audit, which was performed when the item was received.

Video

Video

See Also

© 2015 Microsoft and IndustryBuilt Software. All rights reserved.

JustFoodERP Release 8.00.00.02 | March 2015