In this walkthrough, you will learn how to generate a quality audit for an item that is on a quality hold.

An item that has been put on a quality hold is not considered to be in inventory, and will not be part of an availability calculation. A quality hold is often used for damaged items. A company may want to audit the items on hold to see if any items can be returned to inventory.

Function Background

Function Background

With quality audits, you first need to set up the quality measures and quality procedures.

Quality measures are individual checks that need to be completed in a quality audit. Quality measure codes are assigned to quality procedures. The same quality measure code can be assigned to multiple quality procedures.

A quality procedure is a grouping of quality measure codes. The quality procedure can then be set up so that when an event occurs, a unique quality audit is generated based on that quality procedure. The same quality procedure can be associated with different events but a unique quality audit will always generated when the event occurs.

In the case of Quality Hold quality audits, the audited quantity needs to be tracked. Items on hold cannot be released when an open Quality Hold quality audit exists.

About This Walkthrough

About This Walkthrough

This walkthrough provides an overview on how to do the following:

- Set up a Quality Hold quality audit

- Set rules for posting a Quality Hold quality audit

- Create a quality measure code

- Create a quality procedure

- Generate the Quality Hold quality audit

- Perform the Quality Hold quality audit

- Perform the first quality audit

- Adjust the audited quantity, and release items on hold

- Perform the second quality audit

- Adjust the audited quantity, and release items on hold

Story

Story

The roof leaked at the JF Company, and some sugar was damaged. Five hundred pounds of sugar were put on quality hold, and now an employee needs to perform a quality audit on the sugar to see what can be returned to inventory and what needs to be disposed of. Only a certain amount of sugar can be examined at one time, so the employee will complete two quality audits on the quality hold items.

During the first audit of the sugar, the employee examines 300 pounds and finds that 90 pounds of sugar can be released into inventory. The Quality Processor then records the amount that was audited, and releases the 90 pounds back in to inventory. A second quality audit is automatically generated when the first quality audit is posted.

During the next audit of the sugar, the remaining 200 pounds are examined, and this time 75 pounds of sugar can be released into inventory. The Quality Processor then records the remaining amount that was audited, and releases the 75 pounds back in to inventory.

Prerequisites

Prerequisites

-

Number series is defined for the Quality Procedure Setup Nos. field on the Quality Setup window.

-

Number series is defined for the Quality Audit Nos. field on the Quality Setup window.

-

Quality hold batches are defined on the Quality Hold Batches window.

-

An item has been put on hold. In this case, 500 lbs of SUGAR WHITE ICING (R100420). See the Placing an Item on Quality Hold Walkthrough for more information.

Setting Up a Quality Hold Quality Audit

Setting Up a Quality Hold Quality AuditThe following procedures explain what need to be set up in order to set up a Quality Hold quality audit.

- Set rules for posting a Quality Hold quality audit

- Create a quality measure code

- Create a quality procedure

To Set Rules for Posting a Quality Hold Quality Audit

To Set Rules for Posting a Quality Hold Quality Audit

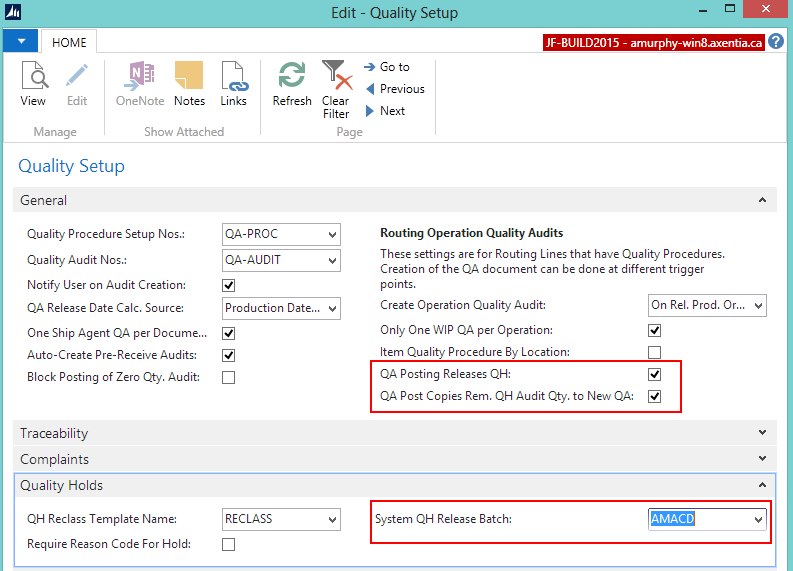

The rules need to be set to indicate what happens when a Quality Hold quality audit is posted.

In the Search box, enter quality setup, and select Quality Setup.

On the General FastTab, select the following check boxes:

QA Posting Releases QH: Selecting this check box means that when the Quality Hold quality audit is posted, any items marked for release will be removed from quality hold.

QA Post Copies Rem. QH Audit Qty. to New QA: Selecting this check box means that when a Quality Hold quality audit is posted, a new quality audit will be created for any items that still need to be audited.

On the Quality Holds FastTab, select a value for the System QH Release Batch field.

-

Click OK.

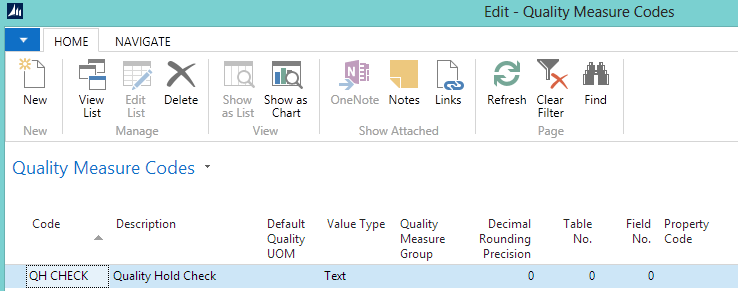

To Create Quality Measure Codes

To Create Quality Measure Codes

The quality measure codes represent the different ways of recording the quality of an item.

Items on a quality hold only need to be visually checked, so only the QH CHECK quality measure code needs to be created.

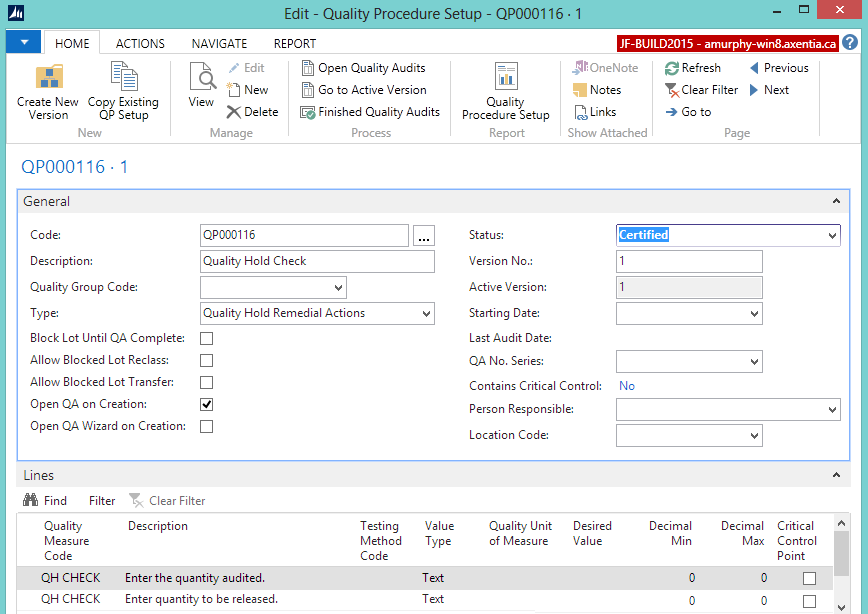

To Create a Quality Procedure

To Create a Quality Procedure

A quality procedure groups quality measure codes, and allows you to record the desired test results. You can create a quality procedure that is specific to quality holds. From the Quality Hold No. Contents window, you can generate a Quality Hold quality audit.

For the JF company, a Quality Hold Check quality procedure is being created.

In the Search box, enter quality procedures, and select Quality Procedures.

Click New. The Quality Procedure Setup window opens.

Enter information on the General FastTab.

Field Description Code

Tab off the field to have the system assign a code. (For a system-assigned code, a number series must be defined for the Quality Procedure Setup Nos. field on the Quality Setup window.)

Description

Enter Quality Hold Check.

Type

Select Quality Hold Remedial Actions.

Open QA on Creation

Select the check box. The Quality Audit window will open once the quality audit is created.

Add the following records to the Lines FastTab.

Quality Measure Code Description QH CHECK

Enter the quantity audited. QH CHECK

Enter quantity to be released. On the General FastTab, change the Status field to Certified.

Click OK.

Generating a Quality Hold

Quality Audit

Generating a Quality Hold

Quality Audit

Prerequisites

Setup procedures were completed.

To Generate a Quality Hold Quality Audit

To Generate a Quality Hold Quality Audit

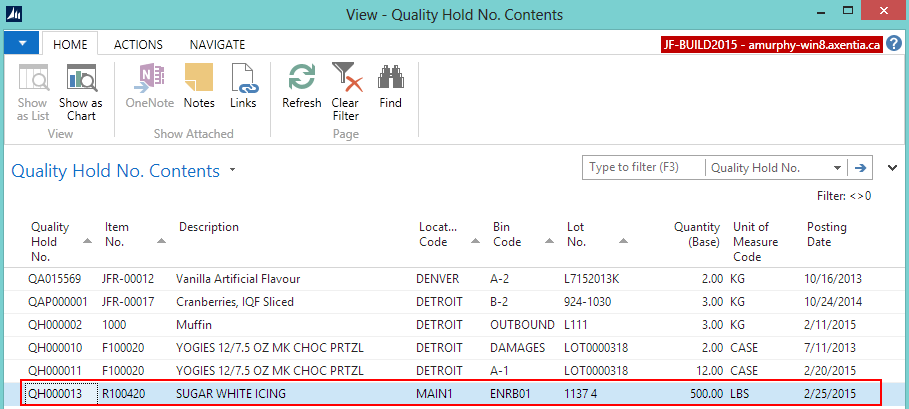

In the Search box, enter quality hold no, and select Quality Hold No. Contents.

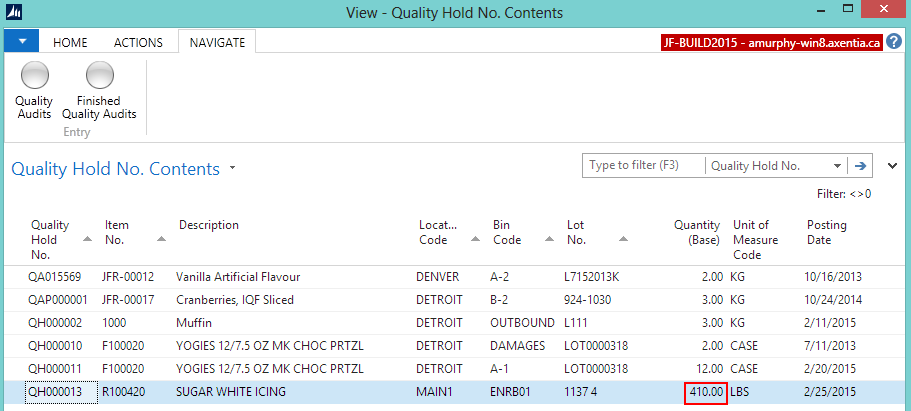

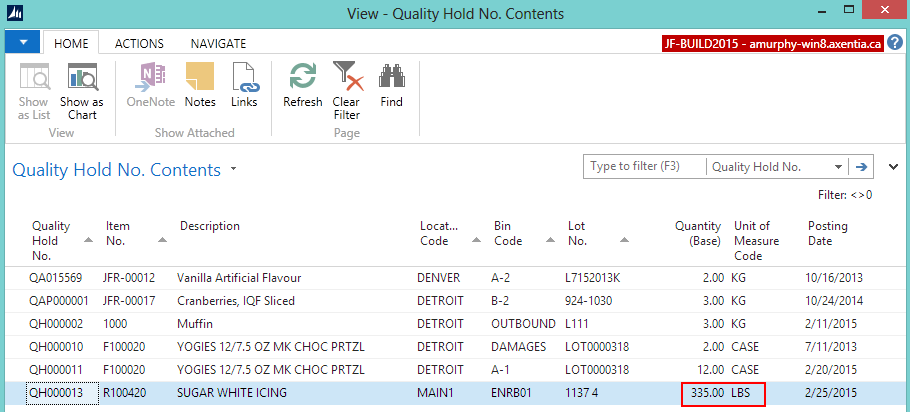

Select the quality hold that you want to create a quality audit for. In this case, SUGAR WHITE ICING (R100420) Lot 11374.

On the Actions tab, choose Create QA Remedial Actions. The QP Setup List window opens with a list of all of the quality procedures where Quality Hold Remedial Actions is the type.

-

Select the Quality Hold Check quality procedure. In this case QP000116.

-

Click OK. A quality audit is created.

-

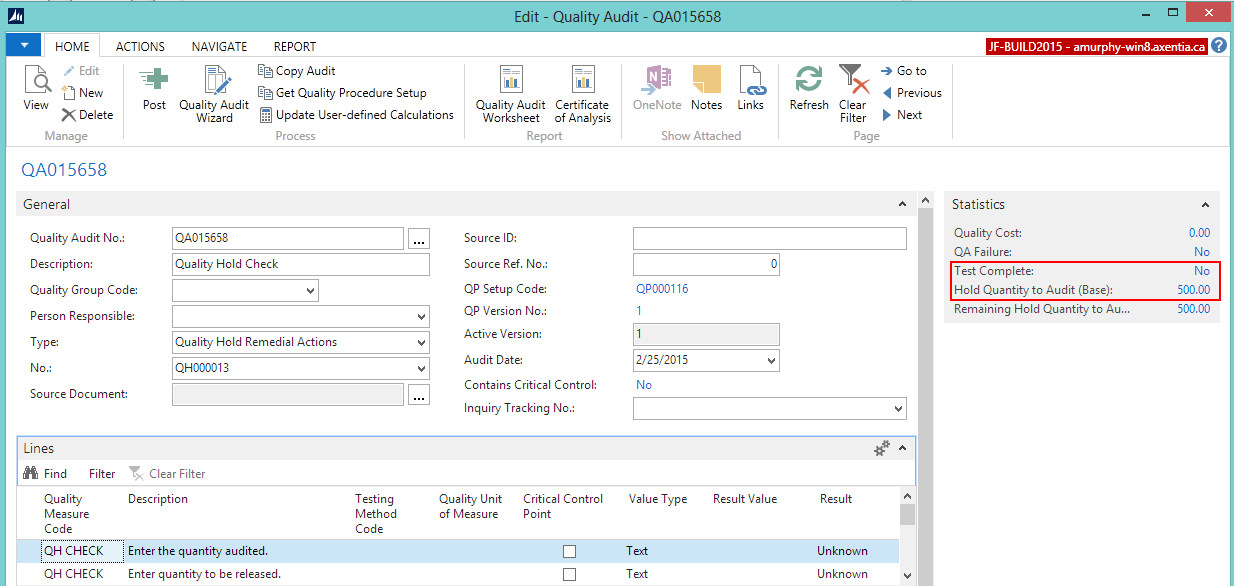

Click OK at the message that a quality audit was created. The QA015658 quality audit is created. The Quality Audit window opens because Open QA on Creation was selected for the quality procedure.

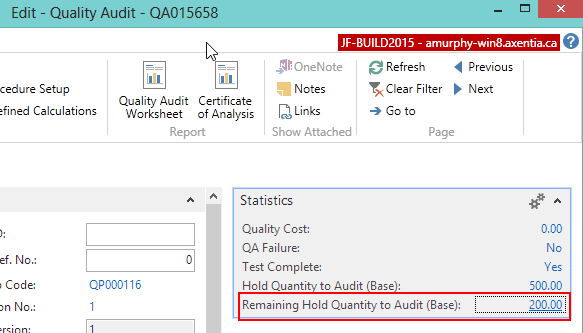

The Test Complete field in the Statistics FactBox shows that the quality audit has not been completed.

The Hold Quantity to Audit (Base) field shows the number of items on hold that still need to be audited.

Performing the Quality Hold Quality Audit

Performing the Quality Hold Quality Audit

An employee performs a quality audit on 300 pounds of the sugar, and finds that 90 pounds can be released back in to inventory. Once the Quality Hold quality audit is posted, the 90 pounds of sugar are released into inventory, and a quality audit is created for the remaining 200 pounds of sugar.

The employee performs a second quality audit on the 200 pounds of sugar, and finds that 75 pounds can be released back in to inventory. Once the second Quality Hold quality audit is posted, the 75 pounds of sugar are released into inventory. A new quality audit is NOT created because all of the hold quantity has been audited.

- Perform the first quality audit

- Adjust the audited quantity, and release items

- Perform the second quality audit

- Adjust the audited quantity, and release items

To Perform the First Quality Audit

To Perform the First Quality Audit

Note: If the Quality Audit window is already open, go to step 5.

In the Search box, enter quality hold no, and select Quality Hold No. Contents.

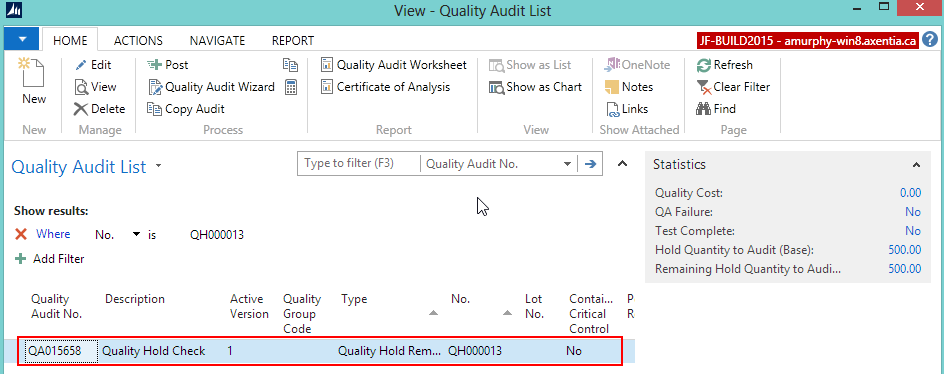

Select the quality hold that is associated with the quality audit that was created. In this case, QH000013.

-

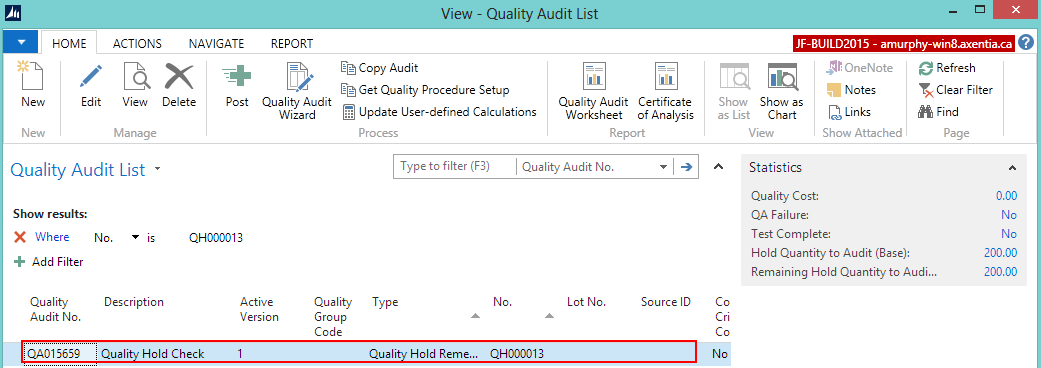

On the Navigate tab, choose Quality Audits. The Quality Audit List window opens.

-

Open the quality audit. In this case, QA015658.

The Quality Audit window opens.

-

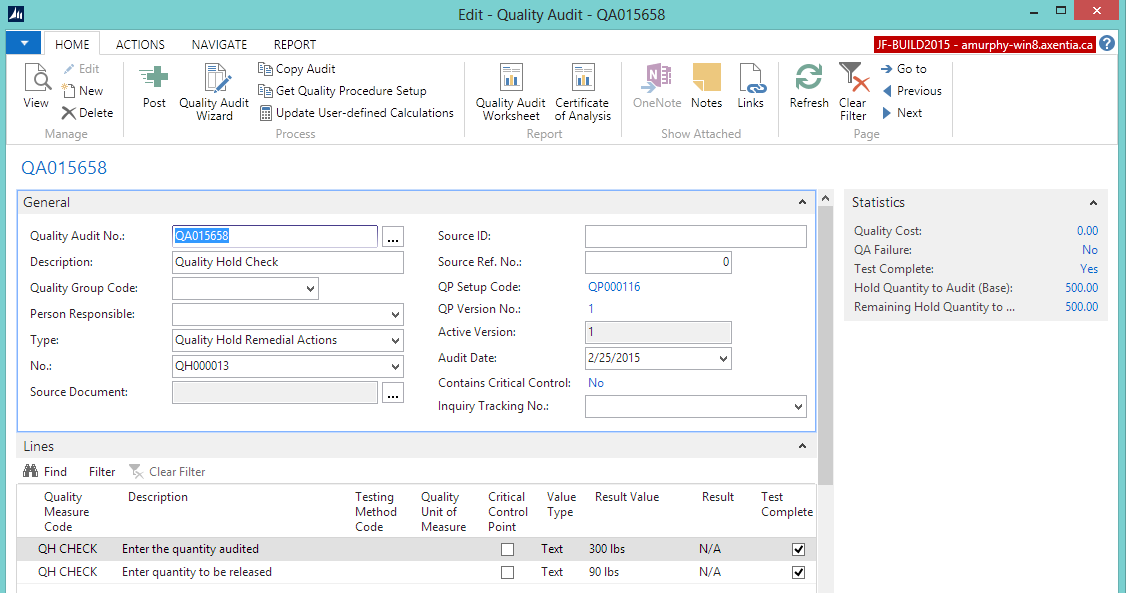

On the Lines FastTab, enter the results of the audit.

Description Result Value Result Test Complete Enter the quantity audited.

300 lbs N/A Select check box Enter quantity to be released.

90 lbs N/A Select check box Do NOT post the quality audit yet.

-

Click OK.

To Adjust the Audited Quantity, and to Release Items

To Adjust the Audited Quantity, and to Release Items

Once the first quality audit is completed, the quantity that still needs to be audited needs to be changed, and the good inventory needs to be released into inventory.

Open the quality audit. In this case, QA015658.

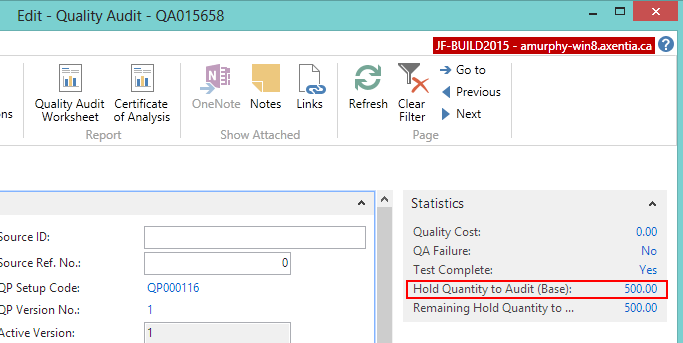

On the Statistics FactBox, click the value for the Hold Quantity to Audit (Base) field. The Quality Audit Hold Tracking window opens.

-

On the Home tab, choose Edit List.

-

In the Audited Quantity (Base) field, enter 300. This is the amount that the employee checked.

-

In the Quantity to Release field, enter 90. This is the amount to release back in to inventory.

-

Click OK. The Remaining Hold Quantity to Audit (Base) field is changed to 200.

On the Home tab, choose Post.

-

Click Yes to post the quality audit.

-

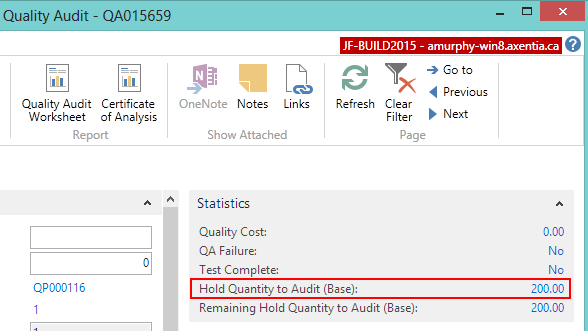

Click OK to acknowledge a new quality audit was created. This quality audit is for the remaining 200 pounds of sugar. The new quality audit opens.

-

Click OK to acknowledge that the first quality audit was posted.

The Hold Quantity to Audit (Base) field now shows 200.

The quantity on hold is now 410 pounds because 90 pounds were released back in to inventory.

To Perform the Second Quality Audit

To Perform the Second Quality Audit

The employee now needs to audit the remaining items on hold.

Note: If the Quality Audit window is already open, go to step 5.

In the Search box, enter quality hold no, and select Quality Hold No. Contents.

Select the quality hold that is associated with the quality audit that was created. In this case, QH000013.

-

On the Navigate tab, choose Quality Audits. The Quality Audit List window opens.

-

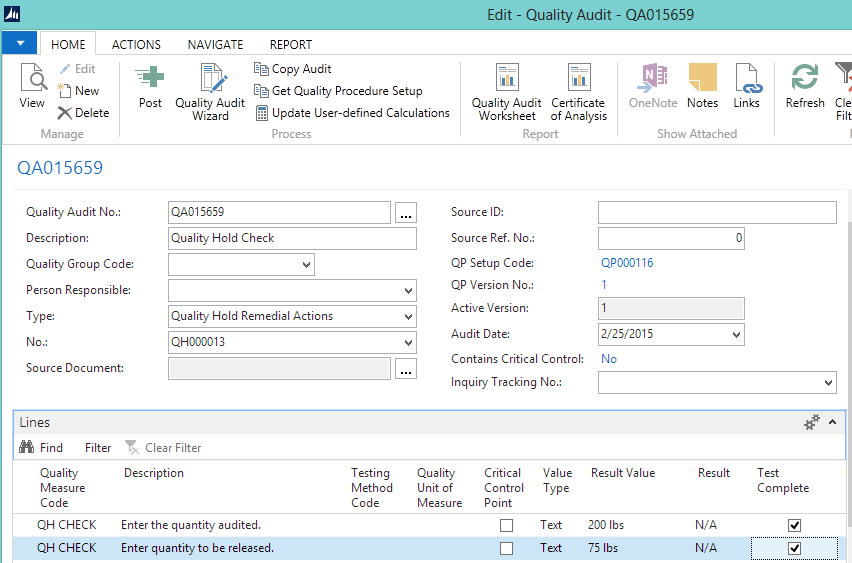

Open the quality audit. In this case, QA015659.

The Quality Audit window opens.

-

On the Lines FastTab, enter the results of the audit.

Description Result Value Result Test Complete Enter the quantity audited.

200 lbs N/A Select check box Enter quantity to be released.

75 lbs N/A Select check box Do NOT post the quality audit yet.

-

Click OK.

To Adjust the Audited Quantity, and to Release Items

To Adjust the Audited Quantity, and to Release Items

Once the second quality audit is completed, the quantity that was audited needs to be changed, and the good inventory needs to be released into inventory.

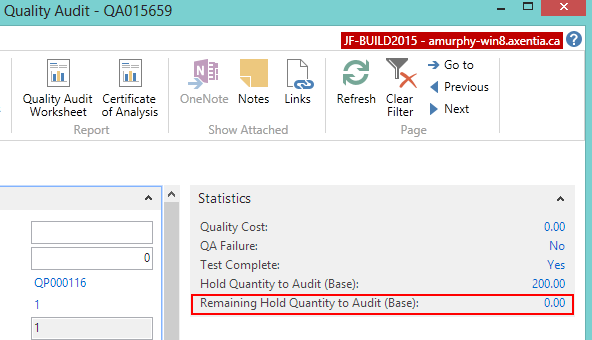

Open the quality audit. In this case, QA015659.

On the Statistics FactBox, click the value for the Hold Quantity to Audit (Base) field. The Quality Audit Hold Tracking window opens.

-

On the Home tab, choose Edit List.

-

In the Audited Quantity (Base) field, enter 200. This is the amount that the employee checked.

-

In the Quantity to Release field, enter 75. This is the amount to release back in to inventory.

-

Click OK. The Remaining Hold Quantity to Audit (Base) field is changed to 0.

On the Home tab, choose Post.

-

Click Yes to post the quality audit.

-

Click OK at the message that the quality audit was posted.

No more quality audits were created because all of the hold items had been audited.

The quantity on hold is now 335 pounds because 75 additional pounds were released back in to inventory.

Video

Video

See Also

© 2015 Microsoft and IndustryBuilt Software. All rights reserved.

JustFoodERP Release 8.00.00.02 | March 2015