When using the Lot In-Serial Out scenario, variable weight items use lot numbers for INBOUND and MOVE transactions, and serial numbers for OUTBOUND transactions, so you need to set up a variable weight item tracking code that includes lot numbers and serial numbers.

To create a variable weight item tracking code

-

In the Search box, enter item tracking, and choose Item Tracking Codes. The Item Tracking Codes window opens.

-

Click New. The Item Tracking Code Card window opens.

-

Enter a value in the Code field that will represent variable weight tracking code.

-

Enter a value in the Description field.

-

On the Serial No. FastTab, select SN Specific Tracking check box, the SN Manufacturing Tracking check box under Inbound, and SN Sales Tracking check box under Outbound.

-

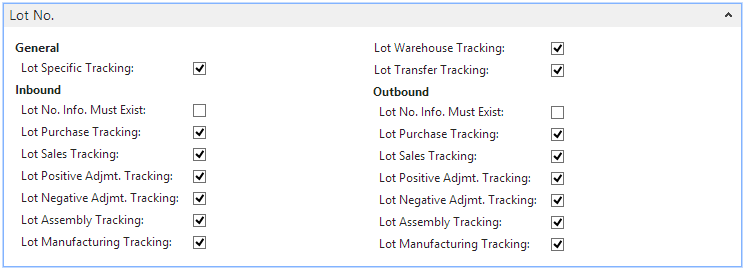

On the Lot No. FastTab, select all of the check boxes except for Lot No. Info Must Exist under Inbound and Outbound.

On the Misc. FastTab, enter the following information:

-

Select the Variable Weight Tracking check box.

-

In the Variable Weight Tolerance % field, enter the percentage that an item's weight can be above or below the item's net weight when item tracking is used. For example, if an item's net weight is 10 pounds and the variable weight tolerance is 10%, then an item's weight would need to be between 9 and 11 pounds on the item tracking lines.

-

Select the Strict Net Weight Posting check box if you want items to require a net weight before any transactions can be posted.

-

Populate the remaining FastTabs as required by your company.

-

Click OK.

Tip Tip |

|---|

For more information about how to work with fields and columns, see Work with Data. For more information about how to find specific pages, see Search. |